Date:2025-06-27 Categories:Product knowledge Hits:520 From:Guangdong Youfeng Microelectronics Co., Ltd

6、 Purpose:

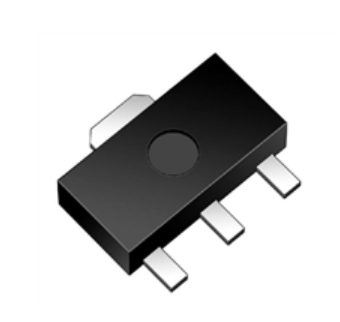

Surface mount transistors are widely used in various electronic devices, including mobile communications, computers, televisions, audio systems, etc. In devices such as mobile phones, televisions, and speakers, surface mount transistors are used for functions such as audio amplification, RF amplification, and switch circuits.

7、 Quality inspection plan:

The quality inspection plan for surface mount transistors mainly includes the following aspects:

1. Appearance inspection: Inspect the appearance of the surface mount transistor, including the color, shape, size, and surface flatness of the casing. Check for obvious defects such as scratches, deformations, or stains.

2. Welding quality inspection: Check the welding quality between the surface mount transistors and the circuit board. This mainly includes whether the amount of solder at the soldering point is sufficient, and whether the connection between the solder pad and the pin is firm. Inspection can be carried out through visual inspection or using a microscope.

3. Pin spacing inspection: Measure whether the spacing between the pins of the surface mount transistors meets the specified standards. You can use a micrometer or microscope for measurement. The inspection results should be consistent with the design requirements.

4. Electrical performance testing: Check whether the electrical performance of the surface mount transistor meets the specified requirements. It mainly includes the following aspects:

a. Static parameter testing: Measure the static parameters of surface mount transistors such as drain current, voltage amplification factor, etc. Specific testing instruments can be used for measurement, such as transistor parameter testers.

b. Dynamic parameter testing: detecting the dynamic response of surface mount transistors under different working conditions. For example, measuring the switching speed, cutoff frequency, etc. of surface mount transistors. You can use instruments such as oscilloscopes for testing.

c. Temperature characteristic test: Test the electrical performance of surface mount transistors at different temperatures. Testing can be conducted using instruments such as a constant temperature chamber or thermocouple.

5. Packaging and labeling inspection: Check whether the packaging of the surface mount transistor is intact and marked with the correct model, production date, batch number, and other information. At the same time, it is necessary to check whether the anti-counterfeiting labels on the packaging are intact.

6. Lifetime testing: Conduct a lifetime test on surface mount transistors to verify their reliability and stability. It can be tested using an accelerated life test bench or a test bench that simulates actual working conditions.

The above is the main content of the quality inspection plan for surface mount transistors. In the actual testing process, the selection of testing items and determination of testing methods should be based on specific quality requirements and product characteristics. At the same time, corresponding testing standards and procedures should be established to ensure the accuracy and reliability of the testing results.

Previous: Classification, Structure, and Principle of MOSFET